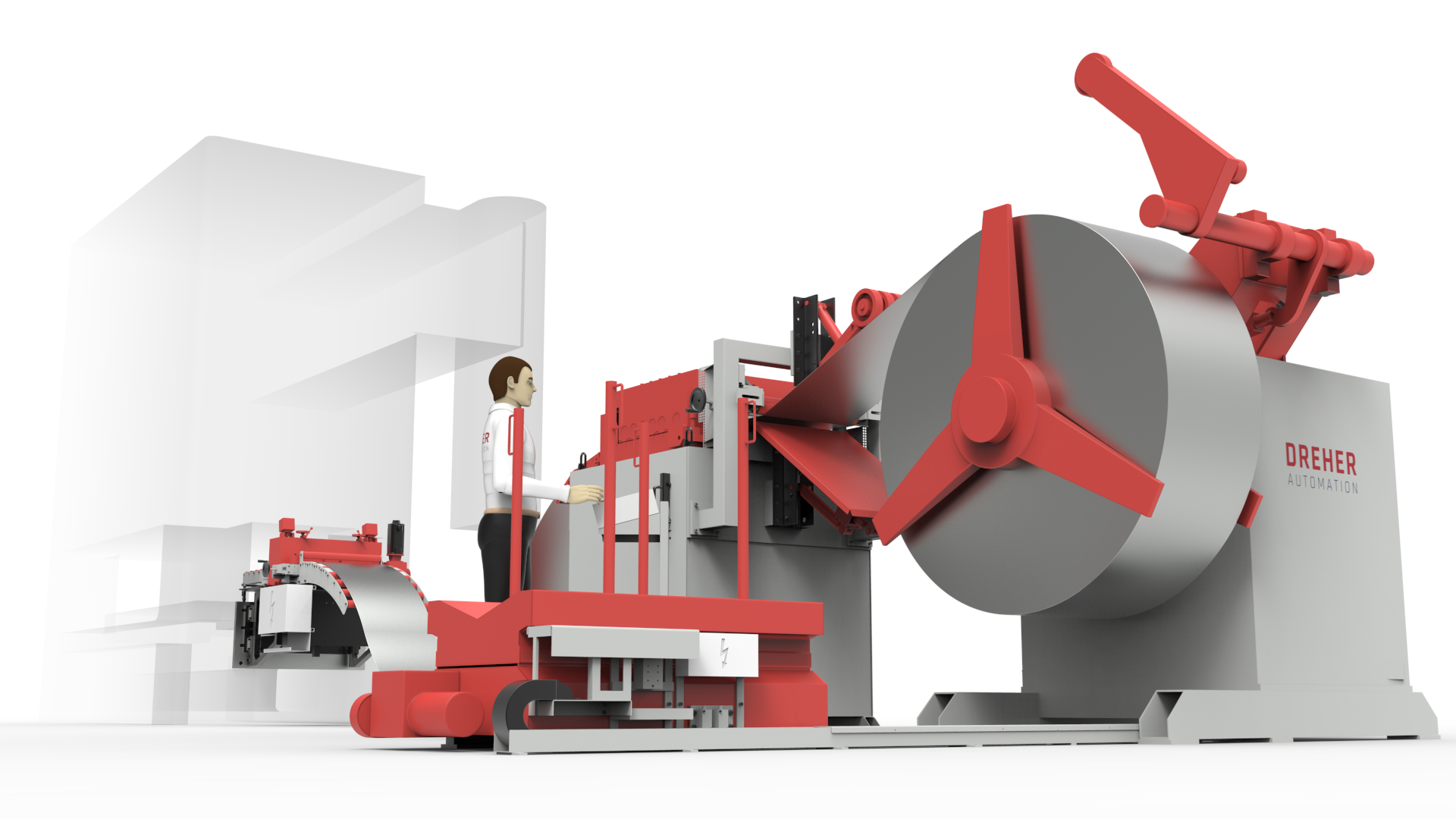

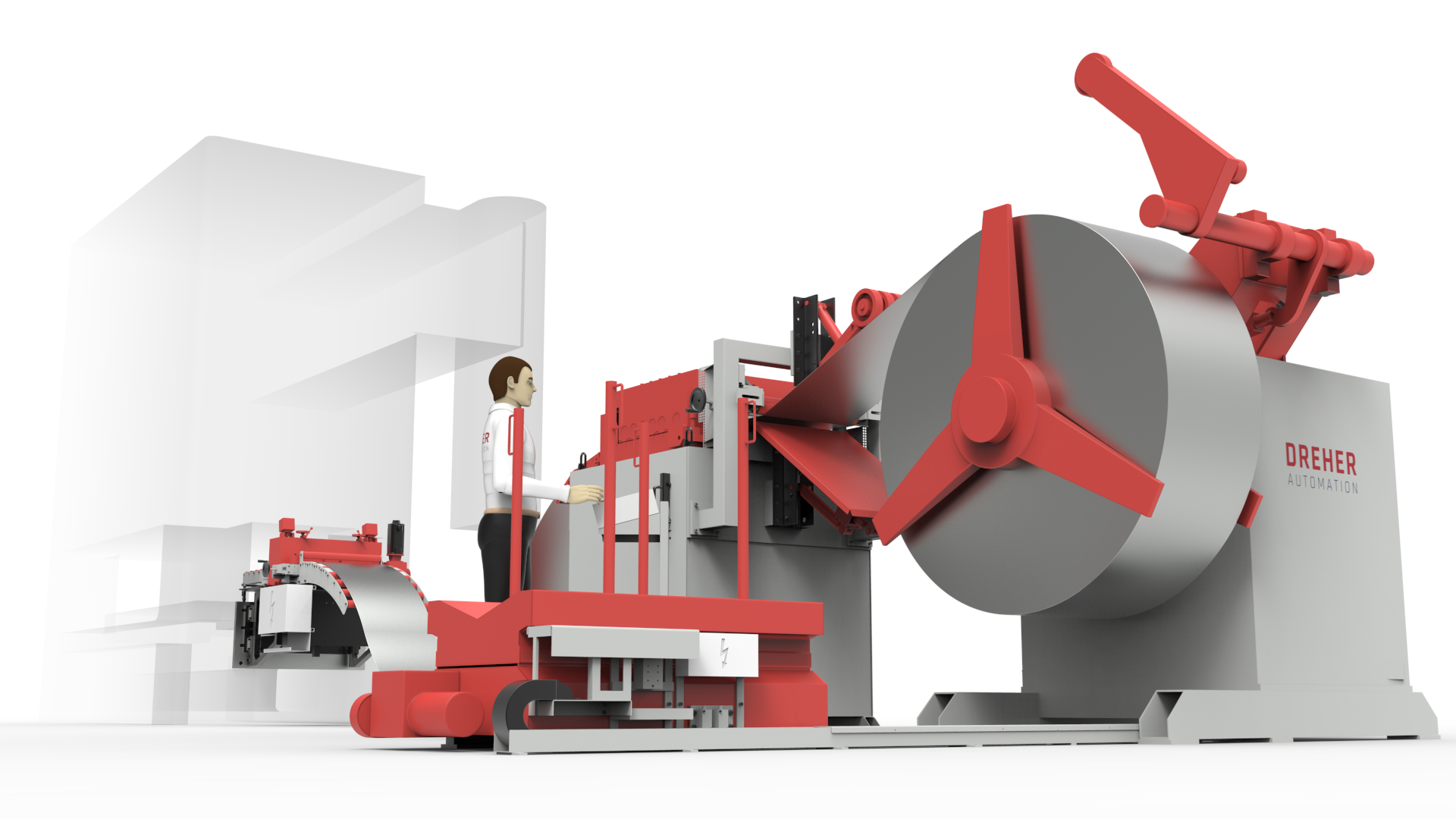

Coil Processing Line

THICK500

Our coil processing line type THICK is particularly well suited for processing thick coil material.

Technical data

Strip width

min. 100 mm - max. 500 mm

Strip thickness

min. 0.8 mm - max. 6 mm

Straightening rolls diameter

90 mm

Coil weight

6 t

Coil outer diameter

1,500 mm

Coil inner diameter

min. 470 mm - max. 530 mm

Coil Loading Car

Specification

- Mobile hydraulic scissor lift

- Coil depot via prism

- Coil tilt protection manually pluggable

Options

- Coil tilt protection swivel mounted

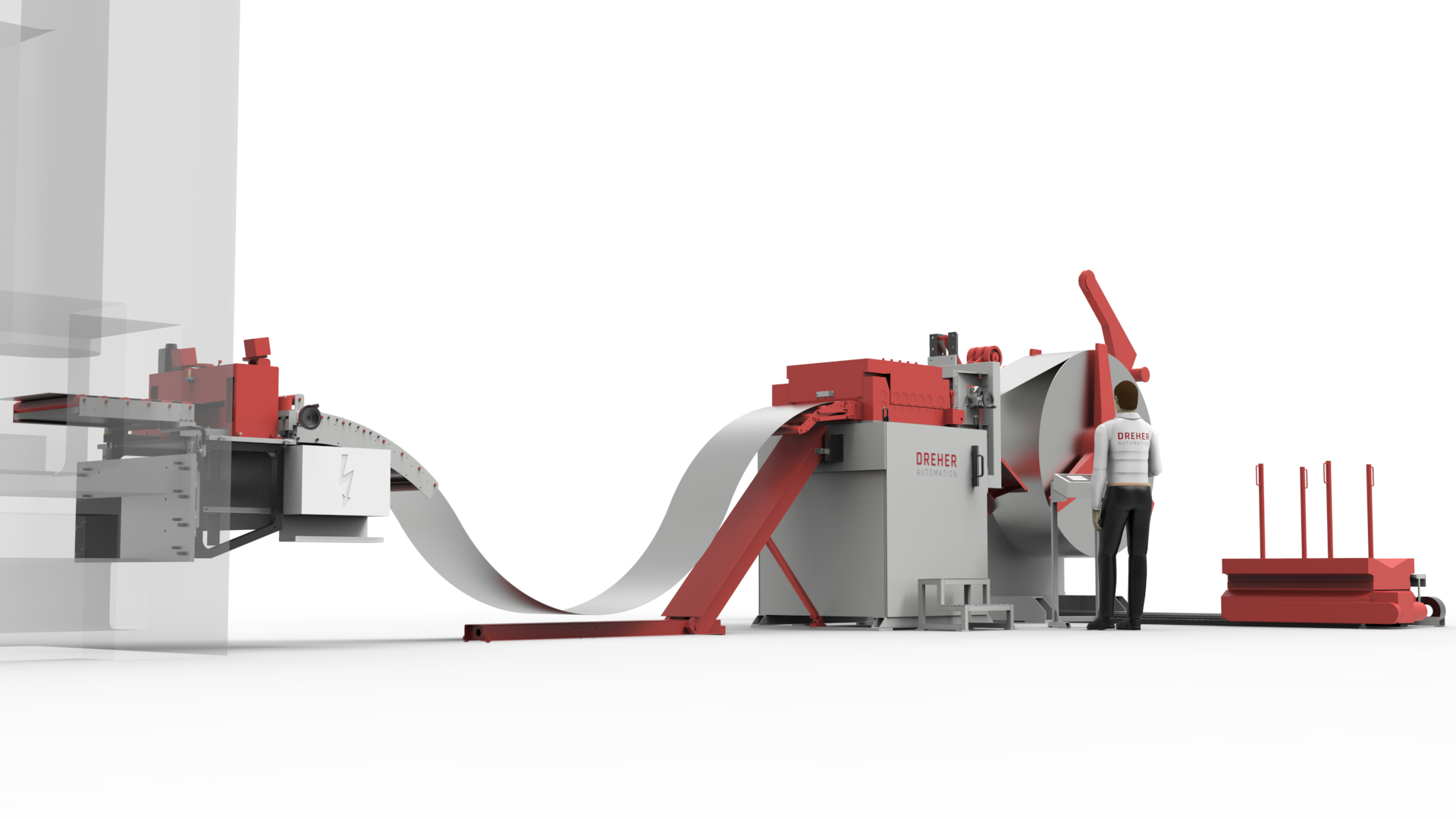

Decoiler

Specification

- Driven decoiler mandrel

- Hydraulic Expansion

- Coil guiding manually pluggable

- Hydraulic pressure roll

Options

- Double decoiler

- Automatic coil guiding with cone rollers

- Interlocking support arms

- Enlargement of expansion area

- Regulated strip decoil control

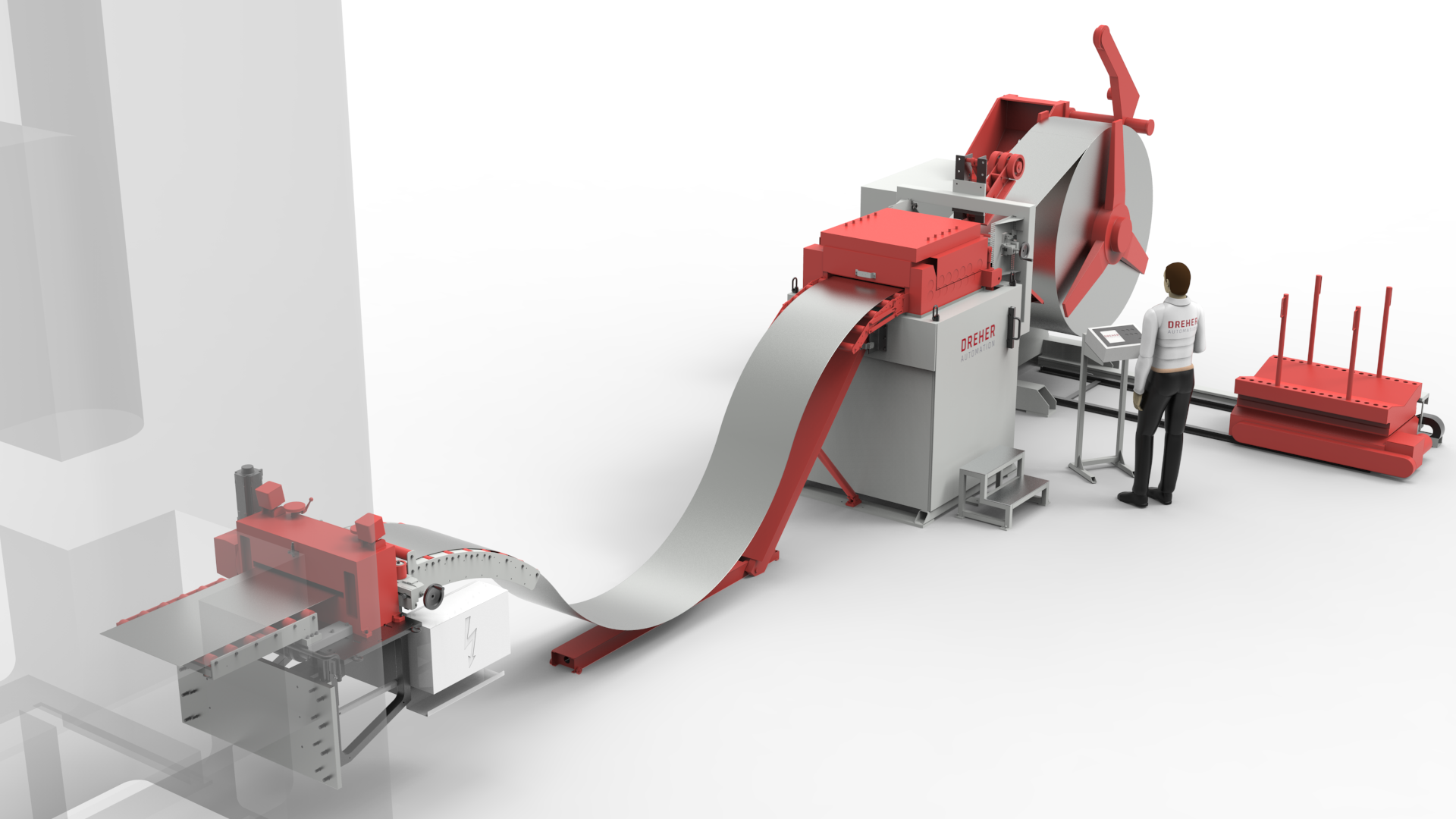

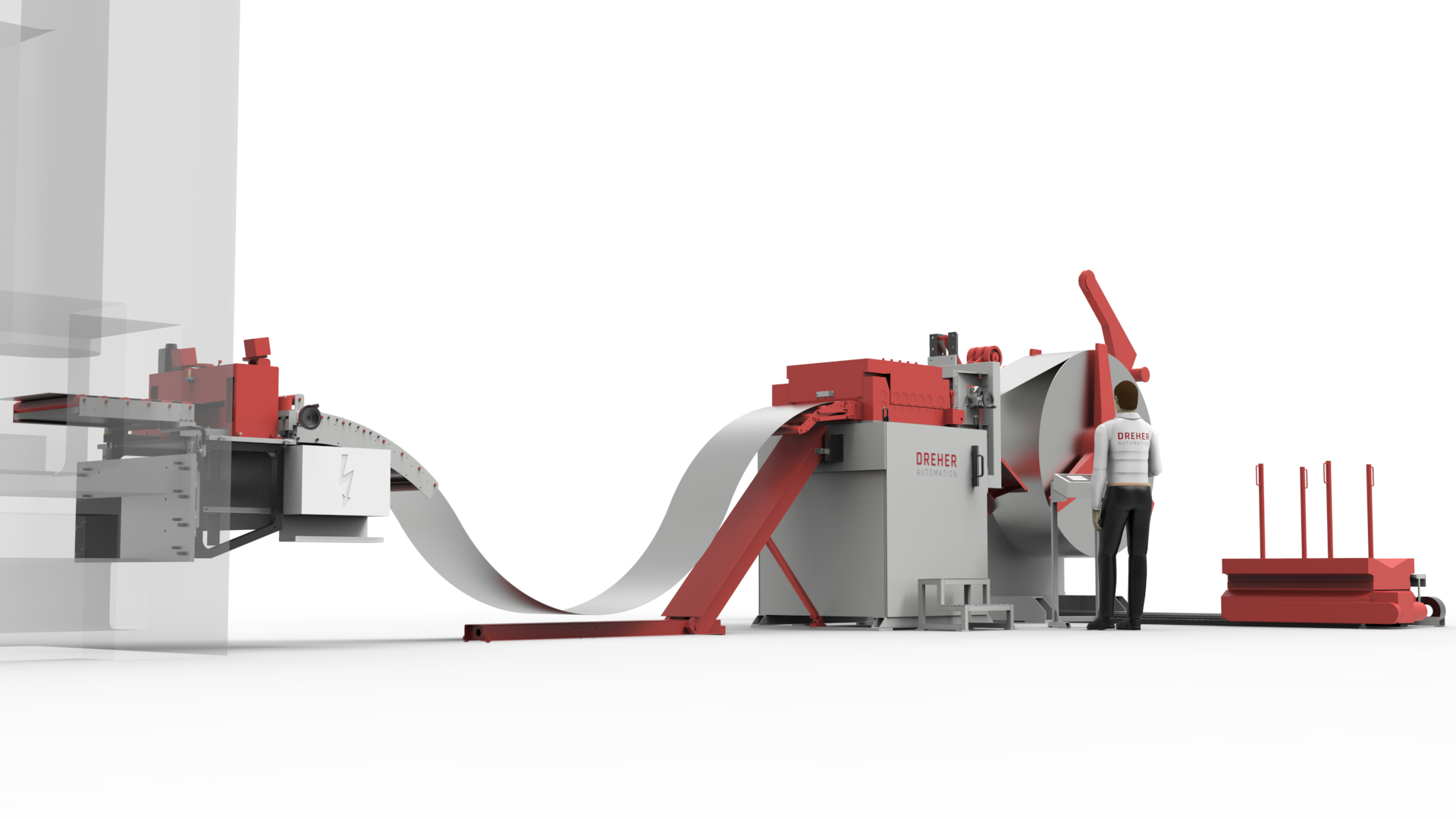

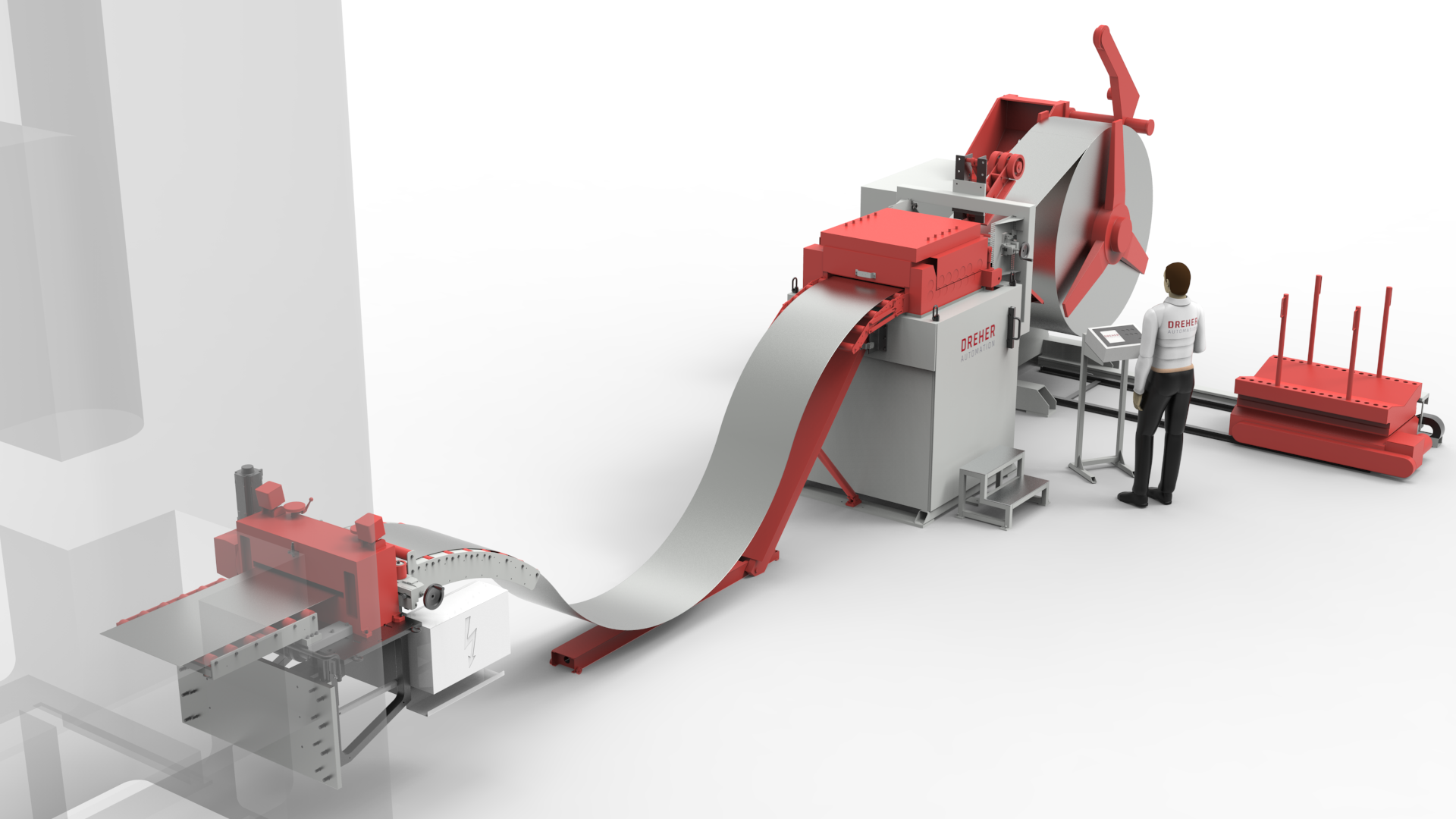

Strip Insertion

Specification

- Strip unwinding from above

Options

- Strip unwinding from above and below

- Strip beginning cutting device

Coil Straightener

Specification

- Straightener head with single roll adjustment

- Manuel adjustment of upper straightening rolls

- Draw rolls inlet and outlet side

- Straightening head openable in transport direction

- Strip guiding inlet side

Options

- Motorized adjustment of upper straightening rolls

- Automatic cleaning device for straightening rolls

Strip Handover

Specification

- Outlet and inlet roller cage

- Loop bridge one-sided

- Automatic strip loop control

Options

- Loop bridge two-sided

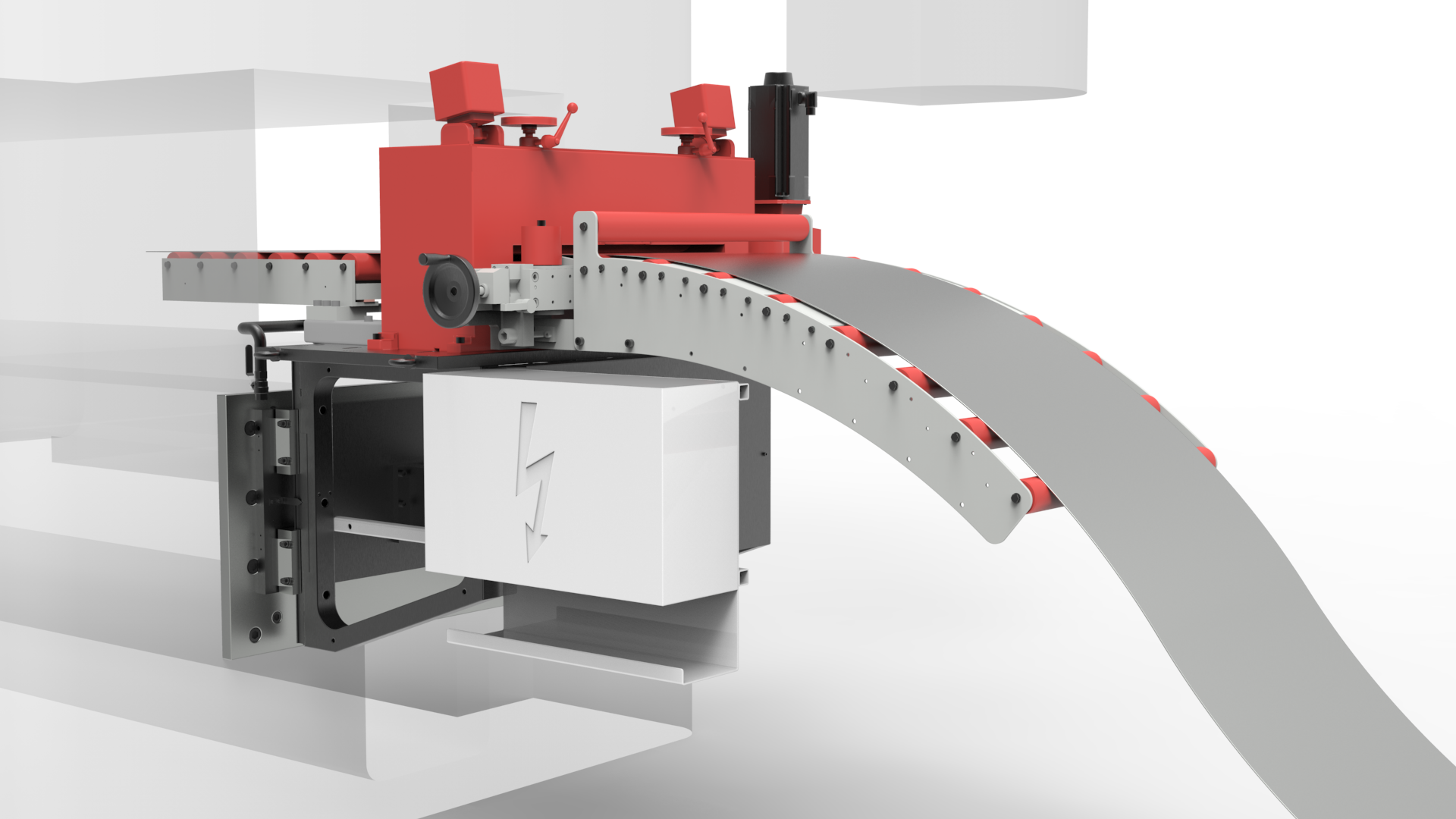

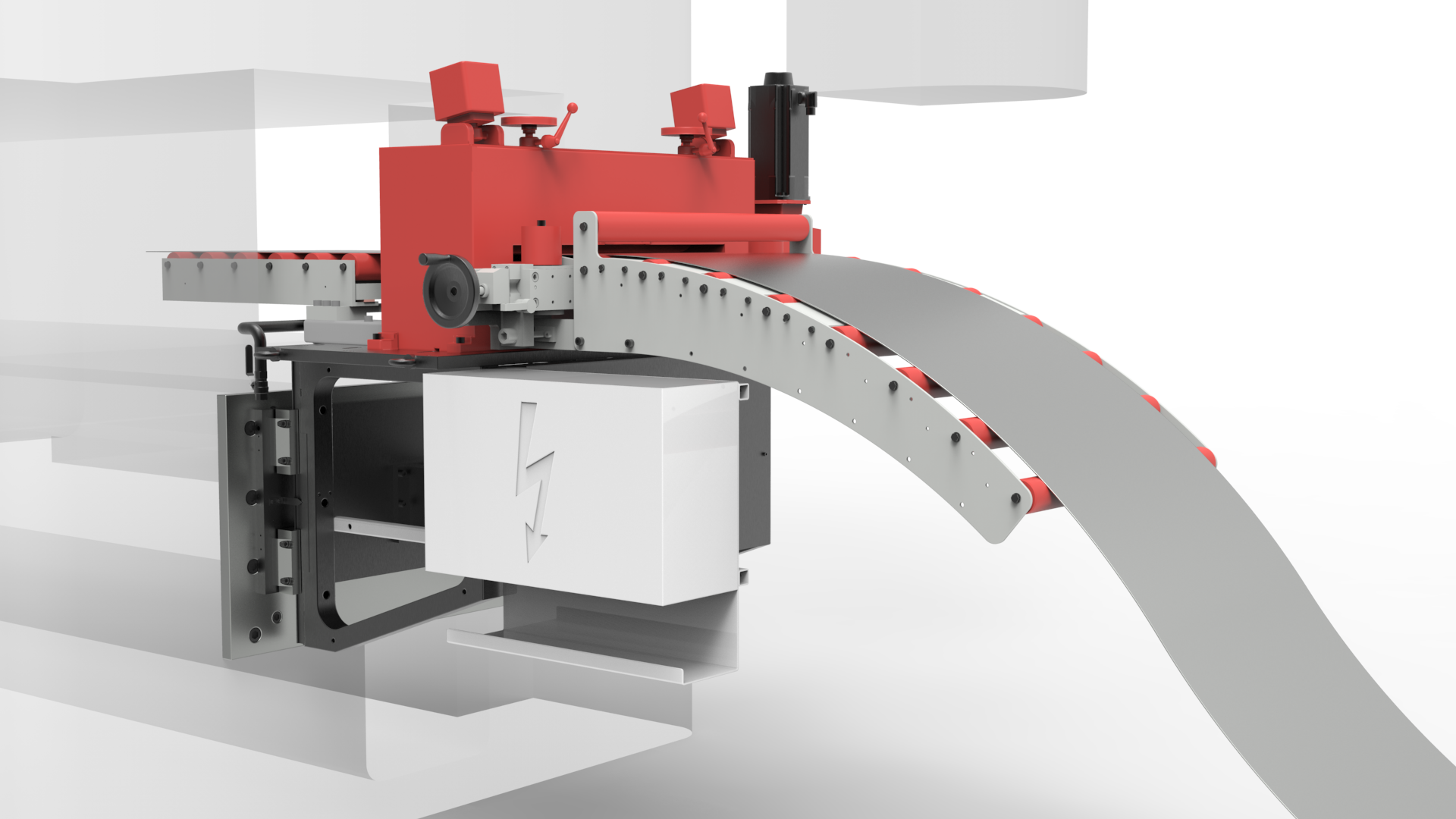

Coil Feeder

Specification

- Attachment to forming press

- Servomotor

- Strip guiding inlet side

- Height adjustment motor driven

Options

- Zig-zag traversing unit

- Cutting device for oddment strip

Automation Level

Specification

- Inching mode via view

- Setting of the strip guiding, straightening rolls and contact pressure manually

Options

- Semi-automatic or fully-automatic

- Setting of the strip guiding, straightening rolls and contact pressure via tool data set

Protection Device

Specification

- Arrangement around 3 sides until press frame

- Light barrier to secure decoiler loading area

Control & Visualization

Specification

- PLC-System Siemens S7

- Drive unit Sinamics

- Safety via Safety Integrated

- Teleservice

- Control panel TP 900

- Visualization with WinCC-Comfort (TIA-Portal)

- Synoptic for automatic operation and coil change

Your Contact Partner

Thomas Rittmann

Senior Sales Manager

- +49 7454 881-502

- +49 7454 881-11

- t.rittmann@dreher.de

Your direct Line to DREHER Automation

Haben Sie Fragen oder dürfen wir Sie beraten? Nutzen Sie unser Anfrageformular – wir freuen uns über Ihr Interesse.