Feeder Automation

Feeder Automation - Design your specific Automation Process with DREHER Automation

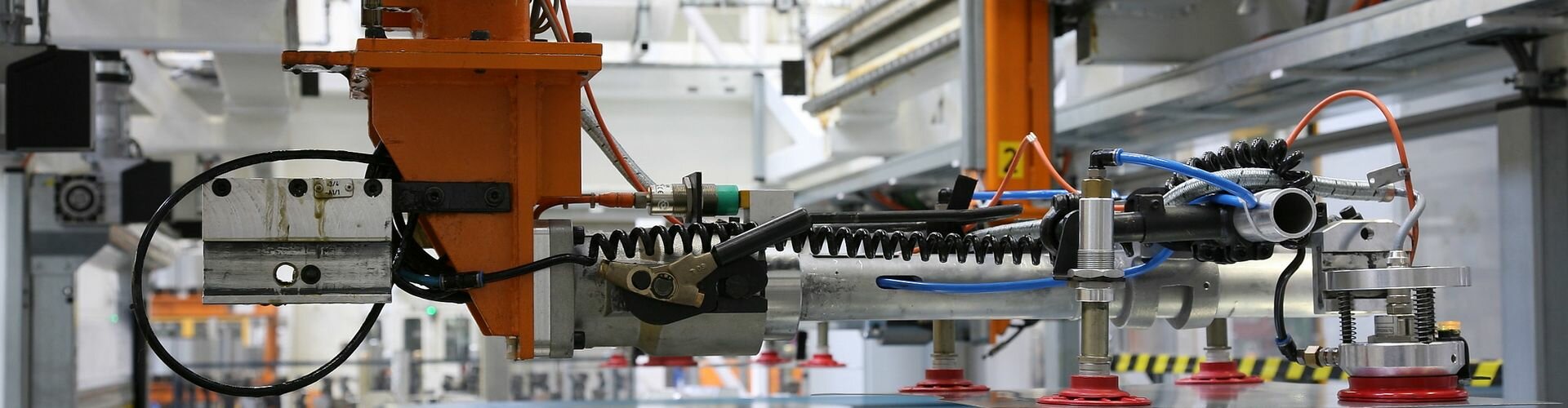

At DREHER Automation, we oversee the entire forming process at your press shop, from the blank right up to the finished formed part. In this case, handling of blanks and formed parts is one of our core competencies. With our feeder automation technology, we offer our customers the ideal solution for fast cycles and reproducible motion sequences, especially for a wide variety of “pick and place” applications.

Our feeders are linear robots specially designed for handling tasks in a press shop. They are used, among other things, for loading forming presses (e.g. by blank loaders), for linking processes (e.g. in press lines) and unloading finished parts (unloading feeders).

DREHER Automation's robust and flexible feeder automation ensures maximum output with maximum availability thanks to linear motion sequences and highly dynamic servo drive technology.

Linear Robots from DREHER Automation - “Pick and place” in a new Dimension

A Feeder automation respectively a linear robot is always the optimal solution for handling tasks in 2D and 3D. Unlike articulated arm robots, linear robots work with the help of linear motion sequences in a horizontal and vertical direction to the machine axis.

At DREHER Automation, we rely on standardized basic sizes for linear robots that cover the entire range of applications in a press shop and beyond in terms of cycle time, part weight, and part size. The linear motion sequences enable optimum cycle times and easy handling of the fully automated process. The robust design of our feeder automation also guarantees maximum process reliability, e.g. through low-vibration parts transport.

Linear robots from DREHER Automation are not only limited to press shop applications. With our large engineering team and professional project management, we are able to adapt our modular feeders to perform a wide range of handling tasks. As a result, we aim to be your preferred partner when it comes to the automation of complex manufacturing processes coupled with robust technology and a high level of availability. We are also happy to supply our linear robots to system integrators - if required - also without our own control unit.

Depending on the application, we can set-up a:

- 2D linear robot with a horizontal and a vertical motion axis

- 3D linear robot with a horizontal longitudinal axis and a transverse axis as well as a vertical motion axis

- 4D & 5D linear robots equipped with a telescopic axis and/or a rotary hand axis

Our linear robots are either connected directly to the machine to be automated or they are designed as “stand-alone” solutions (portal feeders or portal robots).

The perfect Feeder Tooling for your Manufacturing Process

Flexibility is important to us. For this reason, we offer assistance in choosing the perfect tooling for manufacturing your product. Our tooling solutions for your feeder automation can be used independent of your materials, connection and power supply and are individually adapted to the respective production process.

You can benefit from the following tooling:

- Active gripper tooling

- Vacuum tooling

- Electromagnetic tooling

Our toolings are suitable for:

- Magnetic and non-magnetic materials

- All common blanks types (e.g. rectangular blanks, circular blanks or shaped blanks)

- Tailored blanks right

- Formed parts

Increased Efficiency thanks to optimized Tooling Change

When it comes to tool changings, time is money – especially if you produce several products on one production line. Because nothing costs you more than a production line that is in shut down. For this reason, we have developed various tooling changing systems for our customers. All our systems have one thing in common. Tool changing of our feeder automation is always quick and uncomplicated. Choose between a manual tooling change using a quick clamping system or a fully automated tooling change with an integrated tooling rack.

Transparent Siemens Control Concept

DREHER Automation has developed a transparent control concept based on Siemens components for various handling tasks. This has resulted in an integrated automation solution developed in close cooperation with Siemens. The automation system is equipped with the motion control system Simotion D, Sinamics S120 inverters and the latest generation of energy-efficient servo motors from the 1FK series.

The control can be adapted specifically to any application, especially in terms of performance and functionality. The individual axis movements are perfectly coordinated and synchronized with each other. The integration of additional axes remains possible at any time.

Are you interested in a feeder automation respectively a linear robot solution from DREHER Automation?

Your Contact Partner

Gabriele Döhler

Senior Sales Manager

- +49 7454 881-507

- g.doehler@dreher.de

Your direct line to DREHER Automation

Do you have any questions or need some advice? Use our contact form, we’re happy to hear from you.