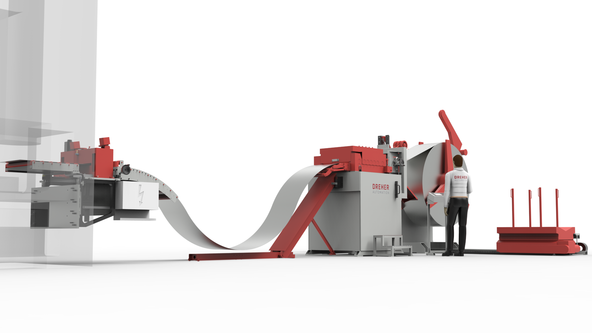

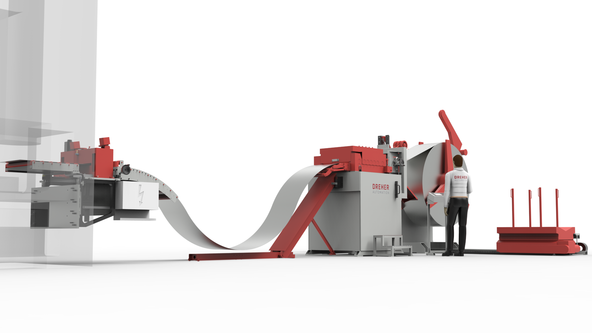

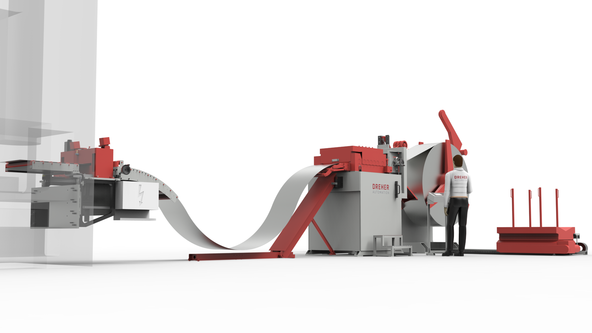

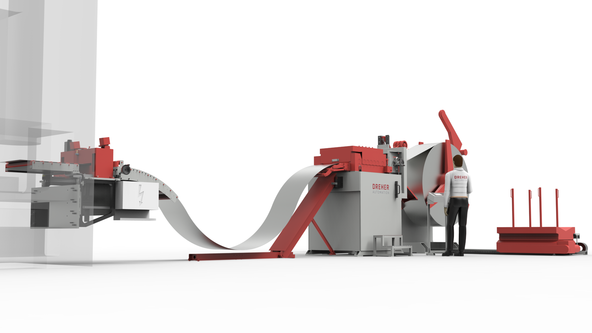

Coil Processing Lines

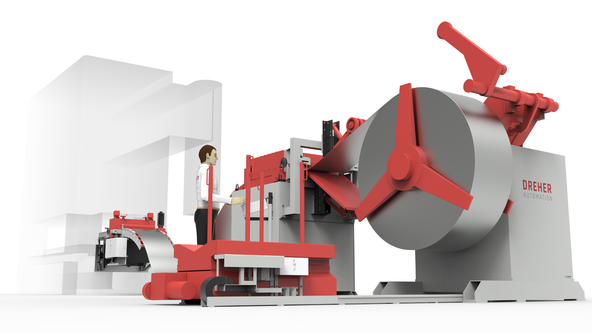

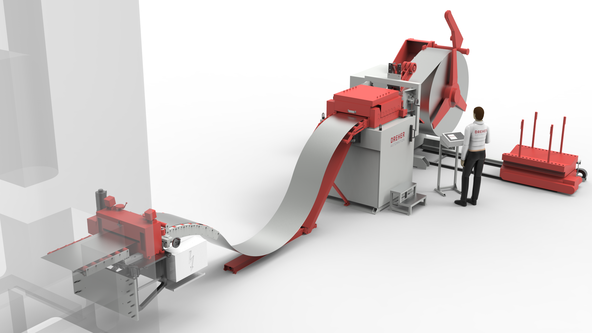

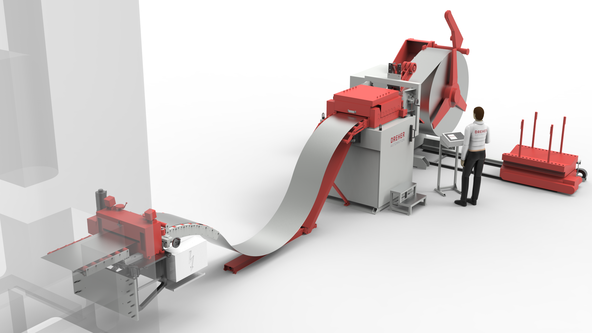

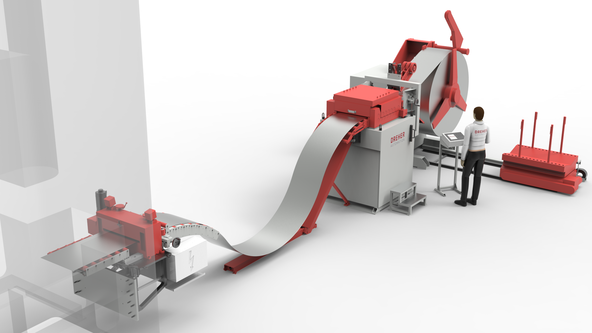

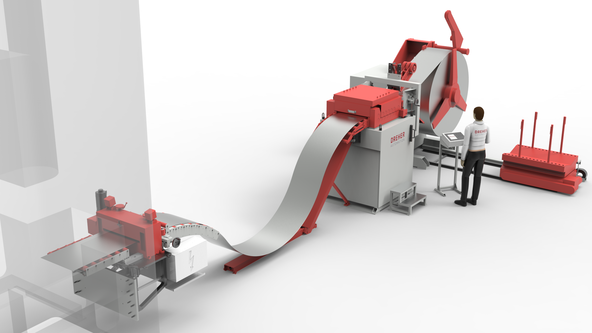

Coil Handling with Coil Processing Lines from DREHER Automation

In a press shop, many process steps must interact seamlessly when processing sheet metal strips (coils). This is our area of expertise! Sheet metal decoiling, straightening, feeding – We adapt everything perfectly to suit your production processes and materials. When selecting the right system concept, we always keep an eye on factors such as the surface quality of the end product, feeding lengths, and space conditions at the intended location.

On request, we can also easily integrate other processes for you, such as washing, oiling, welding or cutting blanks.

The right Coil Processing Line for your Requirements

Depending on your specifications, we build our coil processing lines in both long and short version. A coil processing line in short version is the right choice, if you attach particular importance to low space consumption. At the same time, the planned feeding lengths should be not too long. If your priorities lie with high material quality, even after the forming process, we recommend a coil processing line in long version. After all, the materials are processed especially gently in this case due to the continuous operation of the coil straightener, in contrast to the start-stop operation of a straightener-feeder-combination.

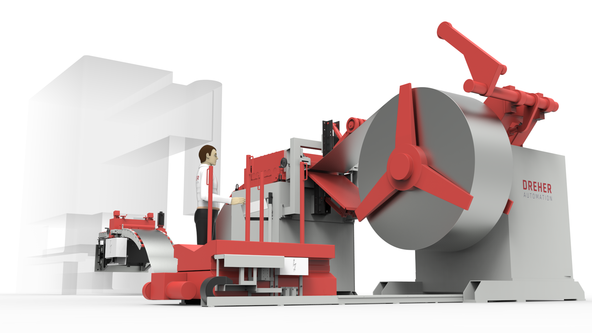

Areas of Application for DREHER Automation's Coil Processing Lines

DREHER Automation coil processing lines can be used for all materials (steel, aluminum, etc.), for all strength ranges and for materials with different surface finishes. When designing our coil processing lines, our focus always lies with your product range. For this reason, we make fundamental decisions based on the following criteria:

- THIN - Coil processing lines designed for thin sheet metal strips

- UNI - Coil processing lines designed for medium material strengths

- TOP - Coil processing lines designed for high and very high material strengths

- THICK - Coil processing lines designed for thick sheet metal strips

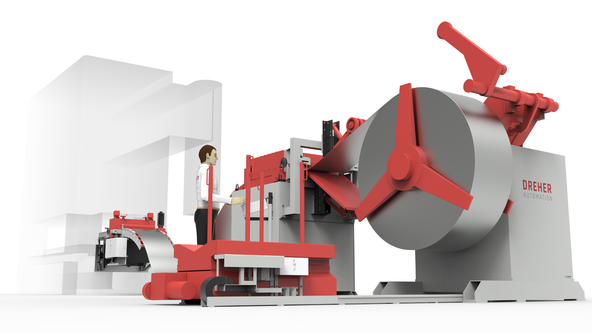

Coil Processing Technology in Press Automation

In the field of press automation, coil processing lines are one of our key technologies. Our wide range of services is always tailored to the respective requirements of our customers. Due to our flexible control concept based on Siemens components for which we have developed the hardware and software, we are also able to individually adapt the operating concept and the automation level of the coil processing line at any time.

You can choose between

- inching mode via view,

- semi automatic, or

- fully automatic.

Our competent project management team will also be happy to support you in the creation of individual coil processing lines that are perfectly adapted to suit the needs of your production process. You will find a wide range of applications in the segments of stamping presses, transfer presses, blanking lines.

Further information about your project workflow with DREHER Automation can be found under project management.

Your Contact Partner

Thomas Rittmann

Senior Sales Manager

- +49 7454 881-502

- +49 7454 881-11

- t.rittmann@dreher.de

Your direct line to DREHER Automation

Do you have any questions or need some advice? Simply use our contact form to get in touch; we’d be happy to hear from you.

Product Portfolio

Stamping Press

Press2perForm 10.000 kN

Stamping PressPress force 10,000 kNTable length min. 3,600 mm - max. 4,100 mmTable width min. 1,400 mm - max. 1,800 mmStrip width min. 500 mm - max. 1,000 mm

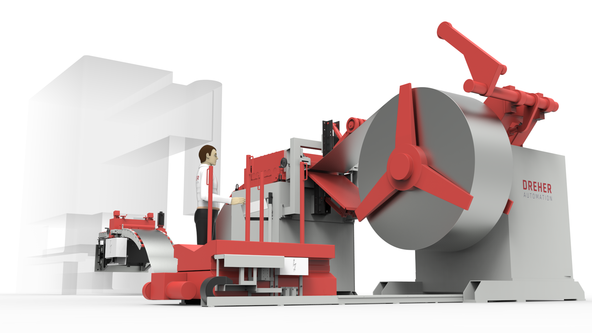

Coil Processing Line

UNI800

Coil Processing LineStrip width min. 100 mm - max. 800 mmStrip thickness min. 0.4 mm - max. 5 mmStraightening rolls diameter 70 mmCoil weight 10 t

Coil Processing Line

UNI1000

Coil Processing LineStrip width min. 100 mm - max. 1,000 mmStrip thickness min. 0.4 mm - max. 4.5 mmStraightening rolls diameter 70 mmCoil weight 15 t

Coil Processing Line

UNI500

Coil Processing LineStrip width min. 100 mm - max. 500 mmStrip thickness min. 0.6 mm - max. 5.4 mmStraightening rolls diameter 80 mmCoil weight 6 t

Coil Processing Line

UNI1300

Coil Processing LineStrip width min. 100 mm - max. 1,300 mmStrip thickness min. 0.4 mm - max. 4.5 mmStraightening rolls diameter 70 mmCoil weight 15 t

Coil Processing Line

THIN500

Coil Processing LineStrip width min. 100 mm - max. 500 mmStrip thickness min. 0.4 mm - max. 3 mmStraightening rolls diameter 50 mmCoil weight 6 t

Coil Processing Line

THIN800

Coil Processing LineStrip width min. 100 mm - max. 800 mmStrip thickness min. 0.4 mm - max. 5 mmStraightening rolls diameter 70 mmCoil weight 10 t

Coil Processing Line

THIN1000

Coil Processing LineStrip width min. 100 mm - max. 1,000 mmStrip thickness min. 0.4 mm - max. 4.5 mmStraightening rolls diameter 70 mmCoil weight 15 t

Coil Processing Line

THIN1300

Coil Processing LineStrip width min. 100 mm - max. 1,300 mmStrip thickness min. 0.4 mm - max. 4.5 mmStraightening rolls diameter 70 mmCoil weight 15 t

Coil Processing Line

TOP500

Coil Processing LineStrip width min. 100 mm - max. 500 mmStrip thickness min. 0.7 mm - max. 6 mmStraightening rolls diameter 70 mmCoil weight 6 t

Coil Processing Line

TOP800

Coil Processing LineStrip width min. 100 mm - max. 800 mmStrip thickness min. 0.4 mm - max. 5 mmStraightening rolls diameter 50 mmCoil weight 10 t

Coil Processing Line

TOP1000

Coil Processing LineStrip width min. 100 mm - max. 1,000 mmStrip thickness min. 0.7 mm - max. 6 mmStraightening rolls diameter 70 mmCoil weight 15 t

Coil Processing Line

TOP1300

Coil Processing LineStrip width min. 100 mm - max. 1,300 mmStrip thickness min. 0.7 mm - max. 6 mmStraightening rolls diameter 70 mmCoil weight 15 t

Coil Processing Line

THICK500

Coil Processing LineStrip width min. 100 mm - max. 500 mmStrip thickness min. 0.8 mm - max. 6 mmStraightening rolls diameter 90 mmCoil weight 6 t

Coil Processing Line

THICK800

Coil Processing LineStrip width min. 100 mm - max. 800 mmStrip thickness min. 0.8 mm - max. 6 mmStraightening rolls diameter 90 mmCoil weight 10 t

Coil Processing Line

THICK1000

Coil Processing LineStrip width min. 100 mm - max. 1,000 mmStrip thickness min. 0.8 mm - max. 6 mmStraightening rolls diameter 90 mmCoil weight 15 t

Coil Processing Line

THICK1300

Coil Processing LineStrip width min. 100 mm - max. 1,300 mmStrip thickness min. 0.8 mm - max. 6 mmStraightening rolls diameter 90 mmCoil weight 15 t

Transfer Press

Press2perForm 6.300 kN

Transfer PressPress force 6,300 kNTable length min. 3,200 mm - max. 3,600 mmTable width min. 1,200 mm - max. 1,600 mmStrip width min. 500 mm - max. 1,000 mm

Transfer Press

Press2perForm 8.000kN

Transfer PressPress force 8,000 kNTable length min. 3,200 mm - max. 4,100 mmTable width min. 1,400 mm - max. 1,800 mmStrip width min. 500 mm - max. 1,000 mm

Transfer Press

Press2perForm 10.00 kN

Transfer PressPress force 10,000 kNTable length min. 3,600 mm - max. 4,100 mmTable width min. 1,400 mm - max. 1,800 mmStrip width min. 500 mm - max. 1,000 mm

Stamping Press

Press2perForm 6.300 kN

Stamping PressPress force 6,300 kNTable length min. 3,200 mm - max. 3,600 mmTable width min. 1,400 mm - max. 1,800 mmStrip width min. 500 mm - max. 1,000 mm

Stamping Press

Press2perForm 8.000 kN

Stamping PressPress force 8,000 kNStrip width min. 500 mm - max. 1,000 mmTable length min. 3,200 mm - max. 4,100 mmTable width min. 1,400 mm - max. 1,800 mm

Stamping Press

Press2perForm 10.000 kN

Stamping PressPress force 10,000 kNTable length min. 3,600 mm - max. 4,100 mmTable width min. 1,400 mm - max. 1,800 mmStrip width min. 500 mm - max. 1,000 mm