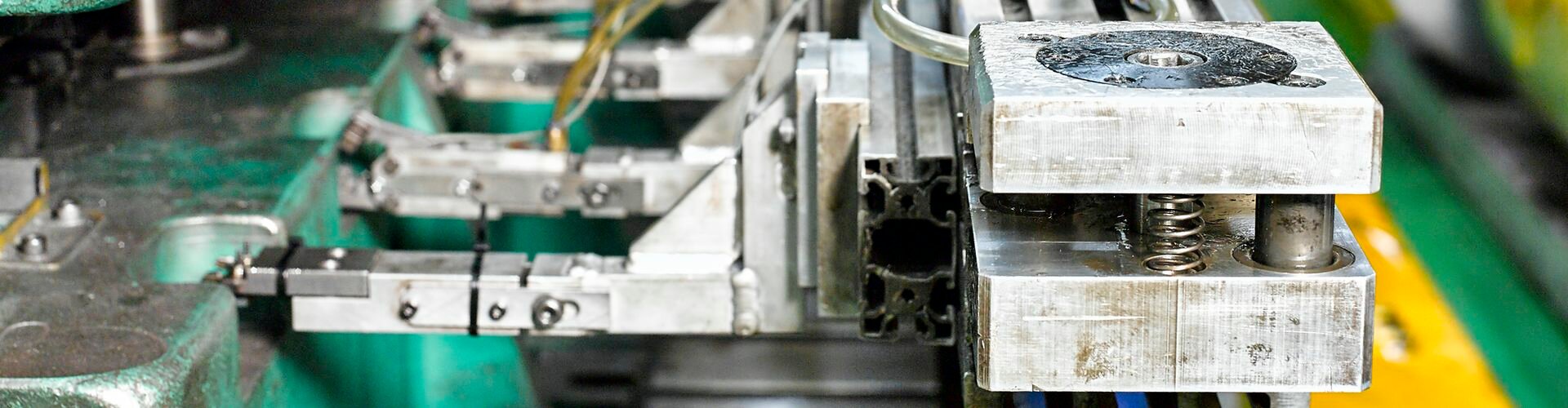

Press Retrofit

Press Retrofit – Innovation through Renovation

Productivity, safety, energy efficiency, and lightweight construction are just a few of the requirements that manufacturers currently have to meet with their systems. But you do not have to buy a new forming system just for this purpose.

Professional Press Overhaul instead of cost-intensive new Acquisitions

DREHER Automation can demonstrate to you how press retrofitting can be a genuine alternative to new acquisitions. We gladly bring your existing forming system in line with the latest mechanical and electrical technology. At the same time, we can find a solution tailored to your individual needs that makes sense and pays off in the long term.

Reasons for a Press Overhoul

- Productivity losses over the life cycle of the forming press

- Increased demands on product quality

- Increased environmental impact due to the high energy consumption

- Limited safety for man and machine due to outdated protection concept

- Limited availability of spare parts

Our Range of Services for your successful Press Retrofit

- Replacement of individual components

- Retrofitting or conversion of existing control systems

- Completely new automation of your existing forming line

- Mechanical retrofitting of your forming line

The Advantages of a Press Retrofit compared to a new Acquisition

- Lower investment costs

- Significantly shorter project duration

- Productivity increase for your existing forming machine

- Availability of spare parts

- Adaptability to current technical developments

- Improved energy efficiency for your machinery

- Improved environmental balance

- Improved safety thanks to modernization

Press overhaul - make your machinery fit for the future

Top performance, individually configurable solutions – standard practice at DREHER Automation. From the technical consultation to an overhauled forming system, we accompany you competently and flexibly every step of the way. As a result, every one of our solutions is unique.

What can you do? Here are some suggestions:

Press Retrofit of a 4,000 kN Stamping Line built in 1982

Press Retrofit of a large-capacity Transfer Press with Blank Destacker

It does not always have to be a complety new line: Professional press overhaul instead of costly new invest! Do you have an outdated forming press, which needs a press retrofit to meet new requirements and to increase your productivity? If yeas, go ahead with the automation expert DREHER Automation! Would you like to receive further information? We would be happy to take care of your enquiry.

Your Contact Partner

Thomas Rittmann

Senior Sales Manager

- +49 7454 881-502

- +49 7454 881-11

- t.rittmann@dreher.de

Your direct line to DREHER Automation

Do you have any questions or need some advice? Use our contact form, we’re happy to hear from you.