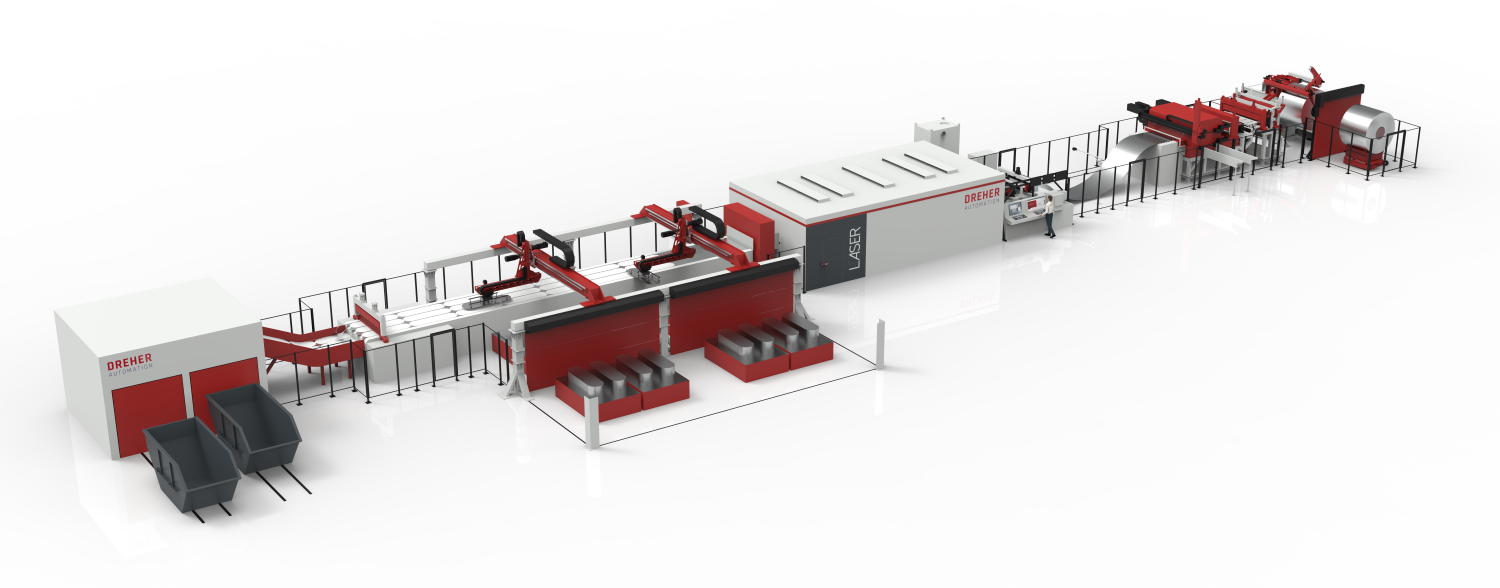

Laser Blanking Line

Laser Cutting with High-Speed Laser Blanking Lines from DREHER Automation

The future of blank production is tool-free, fully automated and digitally networked. With our laser blanking lines for high-speed laser cutting, we are setting new standards in sheet metal processing and meeting the requirements of more than just the automotive and supplier industry.

Our high-speed laser blanking line enables precise and highly dynamic cutting of coil material - directly from the ongoing strip, without a press tool. The combination of agile system technology and intelligent automation with high cutting speeds makes our laser blanking lines the ideal solution for varied series production, decreasing batch sizes and increasing sustainability requirements in your press shop.

Your benefits with a laser blanking line from DREHER Automation

-

Tool-free production: No purchase, storage and maintenance costs for blanking tools

-

Flexible nesting: Maximum material utilization thanks to digital cutting patterns

-

High dynamics: Parallel cutting with two laser heads for short cycle times

- Low waste: Precise cutting quality with reduced material losses at the same time

-

Industry 4.0 ready: Interfaces for process monitoring, data evaluation and AI integration

-

Resource efficiency: Less energy, lower CO₂ emissions, more sustainability

High-speed Laser Blanking - When each Detail counts

Our high-speed laser blanking system is based on our long-term experience in the field of press automation and was developed together with leading industry partners such as the Fraunhofer Institute for Laser Technology (ILT) and the Karlsruhe Institute of Technology (KIT) as well as our development partner BILCUT GmbH. The result: A highly productive laser blanking line that sets new standards in terms of speed, flexibility and sustainability.

Whether for structural components, body parts, non-automotive or individual blanks - our laser blanking technology is the answer to modern production requirements in a volatile market environment.

Pilot Project successfully completed - First Series Line from the End of 2026

Following a successful proof of concept, construction of the first series line for BILCUT GmbH, a member of the BILSTEIN GROUP, will begin in 2025. In autumn 2026, the technology will then be presented to the specialist public for the first time at the next DREHER Automation Days - including a live demonstration from coil to blank stack.

Would you like to find out more about our laser Blanking line? Get in touch with us - we will be happy to consult you individually.

Your Contact Partner

Gabriele Döhler

Senior Sales Manager

- +49 7454 881-507

- g.doehler@dreher.de

Ihr direkter Draht zu DREHER Automation

Haben Sie Fragen oder dürfen wir Sie beraten? Nutzen Sie unser Anfrageformular, indem Sie es über die Schaltfläche ausklappen.