Transfer Presses

Highly productive Transfer Presses for Sheet Metal Forming

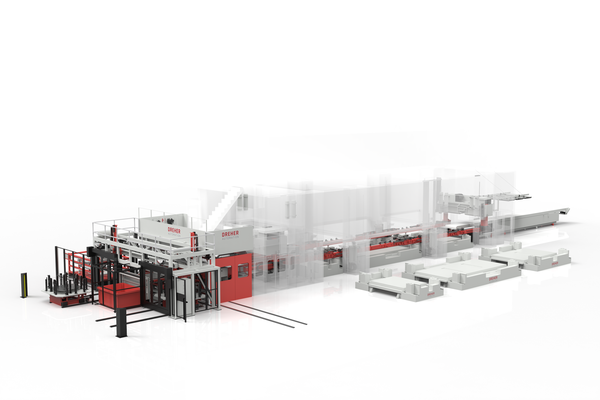

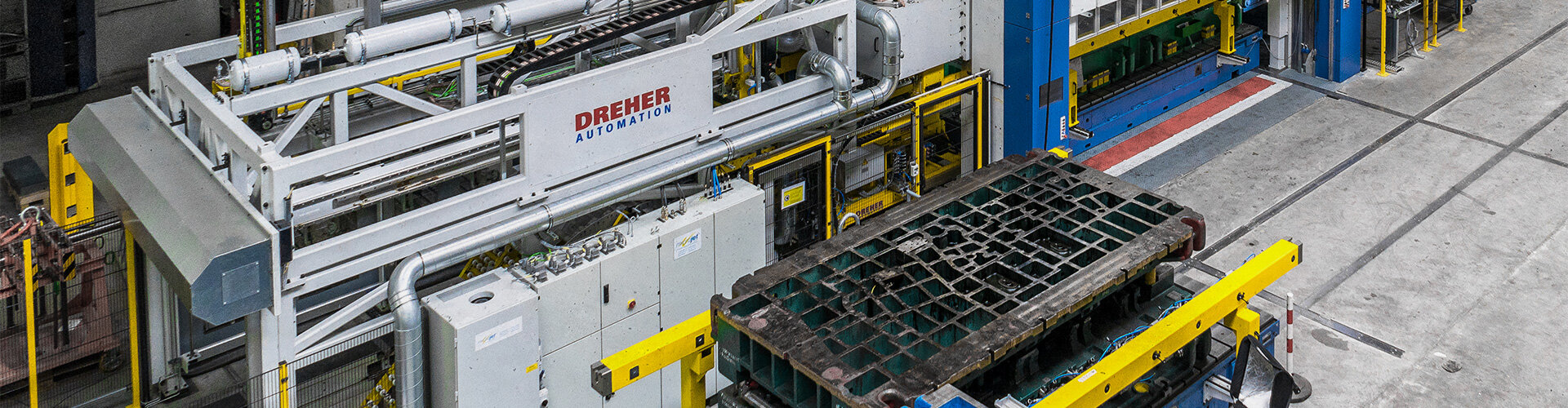

A reliable production process for complex components requires several forming steps. However, using transfer presses is an optimal solution to guarantee an efficient forming process. A consistent and integrated overall press automation concept is the basis for highly efficient production.

For an optimal manufacturing process, all process steps from material supply, through to component handling and discharge of the finished formed product must be perfectly coordinated hand in hand. With our competent project team, not only do we provide you with the perfect transfer automation solution, we also offer a complete concept and support you in choosing the right press partner. The level of automation of the entire forming line depends entirely on your requirements, and the automation concept is determined by your forming process.

The optimal Transfer Press for your Needs

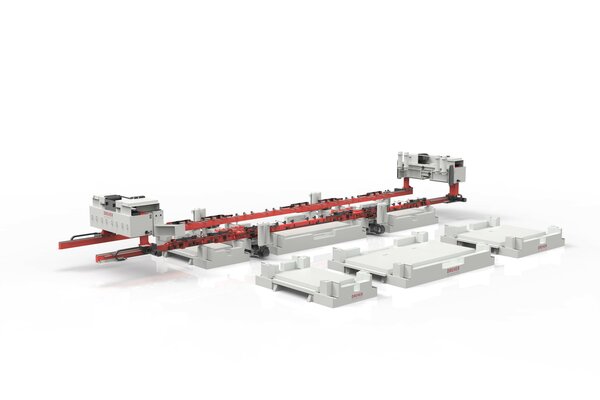

Transfer presses are automated multi-stage forming presses characterized by a high degree of automation. Components for which the forming process is too complex to be reproduced in a single process stage are produced on multi-stage presses. A transfer automation for part transport is used to transport the components automatically through the multi-stage tool or the transfer tool.

Eccentric or toggle presses are particularly suitable for use as transfer presses. Hydraulic forming presses can also be used for large deep-drawing processes or, if flexibility is required, servo presses. Depending on the forming process, the parts are transported in 2D mode (close-feed forward-open-return) or in 3D mode (close-lift-feed forward-feed lower-open-return). Parts can also be transported on one side with clamping grippers or on two sides with grippers positioned underneath and/or also with clamping grippers.

We are happy to support you in cooperation with our competent project team during the implementation of your new production concept. Feel free to contact us!

Material Feed via Coil or Blank? Why not both?

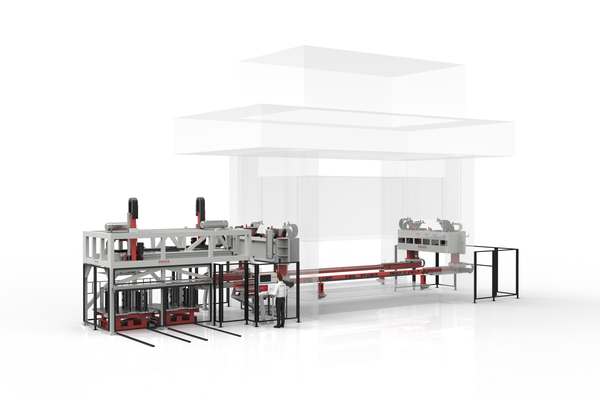

As a rule, a transfer press is fed either via a coil processing line or via a blank destacker or parts loader. At DREHER Automation, we are able to offer you innovative solutions for coil handling as well as blank handling.

Due to the latest developments in forming technology and the automotive industry the demand for flexibility in your production processes is also steadily increasing. So why not use a combination of coil processing line and blank destacker for feeding? In this way, you can process strip materials and blanks on a single transfer press. The integration of a blank buffer or a part buffer to equalize changing times can also be implemented. Or you can use your coil processing line in combination with a blank stacker and a blank destacker as a blanking line when the transfer press is not needed.

After the forming process, the finished components are discharged from the transfer press via a finished parts conveyor, preferably with a removal feeder, or using another end-of-line solution.

Redefine your production process, develop innovative automation concepts with us and increase the productivity of your pressing operation.

Increased Efficiency with an integrated Control Concept

Our control concept developed together with Siemens will complete your comprehensive system concept across all system components (coil processing line, multi-stage tool, and transfer press). Our S7 controller with Safety Integrated (Performance Level d) is not only compatible with any press controller. We can also take care of press control, for example as part of a press retrofit of an existing press.

Furthermore, at DREHER Automation we appreciate the productivity-enhancing advantages of user-friendly and self-explanatory operation and visualization. For this reason, not only does our system visualization take place on spacious touch panels at a central location via WinnCC (TIA portal) - we will also gladly develop a unique visualization concept for the entire forming system for you. Synoptics for automatic operation and sequence synoptics for tool changes are mandatory for all our customers.

The automation level of our systems is always variable. Have you already thought about changing to a fully automatic tool? We work together with you and the press manufacturer to develop an appropriate concept and implement these processes across all components (press automation and forming press).

Our systems are renowned in the industry for their longevity. This is also guaranteed by our excellent After Sales Service. For “just-in-time support”, all our systems are equipped with remote maintenance access.

Your Contact Partner

Marc-Andy Luippold

Senior Sales Manager

- +49 7454 881-501

- +49 7454 881-11

- m.luippold@dreher.de

Your direct line to DREHER Automation

Do you have any questions or would you like us to advise you? Simply fill out our contact form, we look forward to hearing from you.